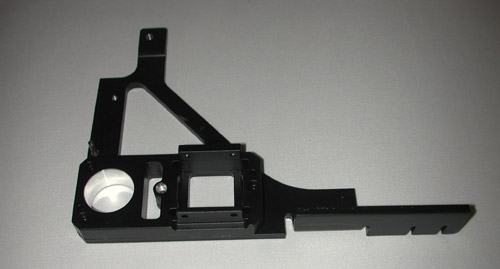

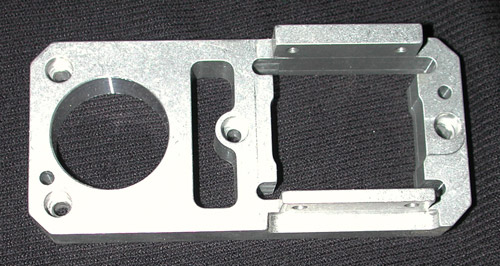

CNC Machining & Metal Stamping of an Assembly for Equipment to Process Hard Disk Drives

One of our clients came to us for help reducing the cost of a large CNC machined and stamped, three dimension bracket, which they were manufacturing for one of their customers. The product was constructed of Aluminum sheet and bar stock. It combined precision CNC machining with metal stamping and required riveting and prep for powder coating. The part also required stamping, riveting, and prep for powder coating.

We decided on a solution that would combine two of AmeriStar’s main capabilities: custom CNC machining to precise dimensional tolerances and surface finishes, and precision metal stamping.

The finished assembly was produced at a 40% savings to our customer. Initial tooling costs where less than $2,000, with a first article production of six weeks. Over the past eight years, we have supplied this customer with over 75,000 of these assemblies. To learn about our other services, please contact AmeriStar.

The finished assembly was produced at a 40% savings to our customer. Initial tooling costs where less than $2,000, with a first article production of six weeks. Over the past eight years, we have supplied this customer with over 75,000 of these assemblies. To learn about our other services, please contact AmeriStar.

CNC Machining & Metal Stamping Project Highlights

| Product Name | CNC Machined and Stamped Assembly |

| Project Scope | Create an assembly that will drive costs out of the current product while maintaining all of the functional requirements. |

| Capabilities Applied/Processes |

|

| Tightest Tolerance | +/-.001” |

| Material Type | Aluminum Sheet and Bar Stock Cold Rolled Steel (CRS) |

| Material Thickness | 1” thick Aluminum Bar Stock 1/8” thick stamped Aluminum |

| Product Length | 12” |

| Product Width | 10” |

| Product Height | 2” |

| Material Finish | Powder coated |

| Industry for Use | Capital/Process Equipment |

| Tooling Cost | $2000 |

| Standards Met | Customer supplied design and prints |

| Volume | Over an eight year period, 75,000 of these assemblies were delivered |

| Delivery Time | 6 weeks |

| Delivery Location | Atlanta, Georgia |